- This event has passed.

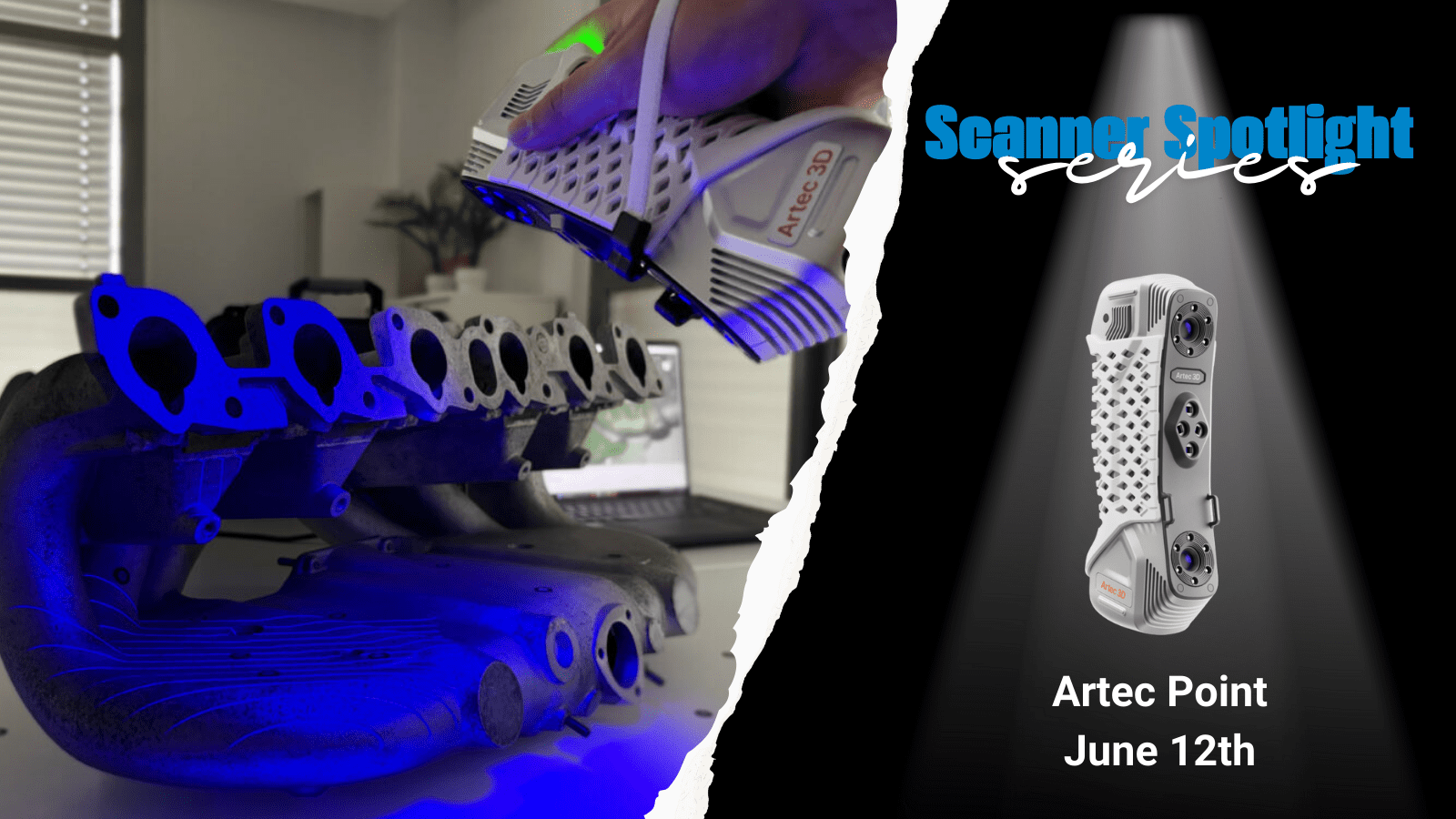

Artec Point Webinar – Scanner Spotlight Series

Each month, we’re hosting a live webinar to give you an in-depth look at one of today’s top handheld 3D scanners. These sessions are a chance to explore the standout features of each device, get expert tips on best practices and troubleshooting, and see how they perform in real-world applications. At the end, we open the floor for live Q&A so you can get your questions answered directly by our engineering team. In our most recent session we put the spotlight on the new FARO Leap ST, to showcase its capability in the 3D Handheld Scanner landscape.

For the month of June, we’re featuring the Artec Point, Artec 3D’s first handheld metrology scanner designed specifically for high-precision industrial use. Built to meet the demands of quality control, reverse engineering, and inspection in industries like aerospace, automotive, and advanced manufacturing, the Artec Point delivers ISO-certified, metrology-grade 3D scanning with accuracy down to 0.02 mm. This kind of precision ensures your data is reliable, repeatable, and ready for even the most exacting workflows.

What sets the Artec Point apart is its ability to handle challenging surfaces with ease—including shiny, black, or intricately detailed parts that often trip up other scanners. Its versatile scanning modes (grid, parallel, and single-laser) give users more control to adapt to different scanning needs, while dual HD cameras positioned at a steep angle allow it to capture narrow or hard-to-reach areas with clarity.

Speed is another key advantage: the Artec Point captures 3D data at 120 frames per second, translating to 2.8 million measurements per second. That means complex projects can be completed faster—without compromising on detail or accuracy. The scanner’s lightweight yet durable metal chassis also makes it suitable for demanding environments, combining rugged reliability with portability.

Another major benefit? The Artec Point runs in Artec Studio—just like the rest of the Artec lineup. That means the learning curve for existing users is practically zero, and you can combine scan data from multiple Artec scanners in a single session, merging everything into one seamless mesh. It’s a powerful workflow boost that makes multi-scanner setups easier and more effective than ever.

When it comes to 3D scanning, there’s no one-size-fits-all solution—and that’s exactly why Artec offers a lineup of powerful tools to meet a range of needs. For straightforward jobs, a single scanner might be all it takes. But for more intricate or large-scale projects, pairing multiple scanners can be the key to working more efficiently and capturing every detail with confidence.

If you’re looking to elevate your metrology capabilities or simply want to stay up to date with the latest scanning technologies, this session is for you. Bring your curiosity and questions—we’ll show you why the Artec Point is quickly becoming a favorite in the world of industrial 3D scanning.

If you missed the live webinar, check out the post recording on our youtube channel – Artec Point Scanner Deep Dive – Scanner Spotlight Webinar.