Why Choose QuickSurface for Solidworks?

1.

Seamless Solidworks Integration

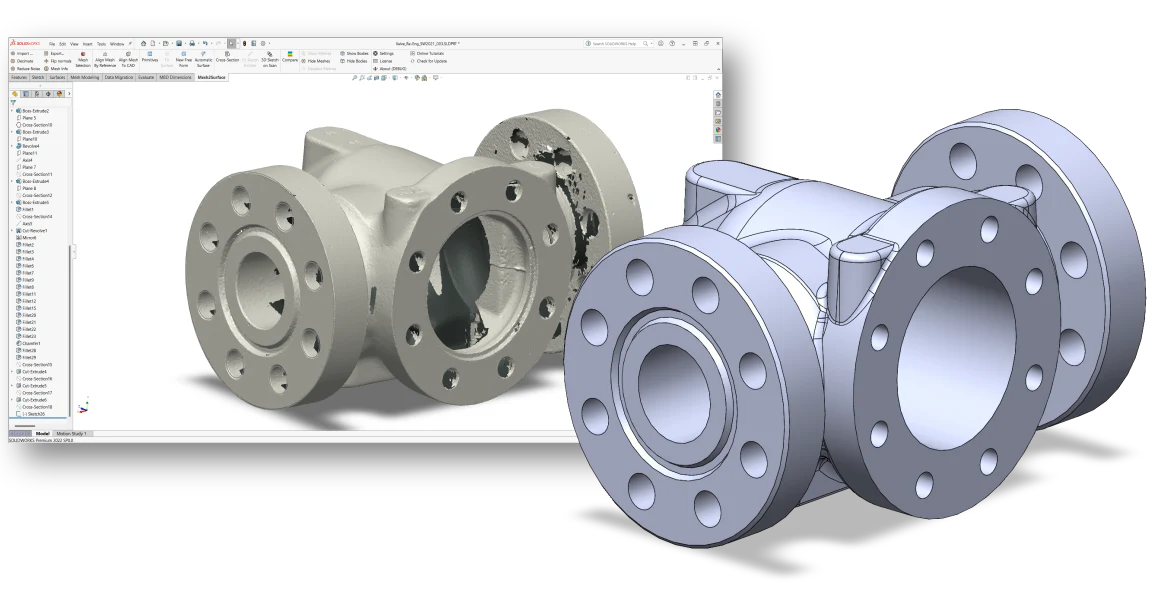

QuickSurface is fully integrated into the Solidworks desktop environment, allowing users to reverse engineer directly within the software they already know and use. This eliminates the need to switch between programs, maintaining a smooth and familiar workflow. The add-in’s intuitive interface and Solidworks-native functionality make it easy to learn, while offering powerful tools for mesh manipulation, geometry extraction, and surfacing. This integration ensures users can work efficiently without sacrificing precision.

2.

Efficient Reverse Engineering

With QuickSurface, users can cut reverse engineering time by more than half compared to traditional methods. The add-in’s advanced algorithms simplify the process of converting complex 3D scan data into accurate CAD models. Features like automated surfacing and intelligent geometry extraction make it possible to quickly transform raw scan data into a usable CAD format. The built-in real-time deviation analysis tool ensures models are accurate, instantly comparing scans to the CAD data for quality control throughout the process.

3.

Advanced Freeform Modelling

QuickSurface excels at handling intricate, organic, and freeform shapes that are difficult to model with standard CAD tools. The software’s proprietary snap-to-mesh technology allows users to accurately recreate complex surfaces with minimal effort. Even users with little experience in freeform modelling can quickly and easily construct detailed CAD models from scan data. This makes QuickSurface particularly valuable for industries like automotive, aerospace, and product design, where complex geometries are common.