Effortless Shift to Digital Models

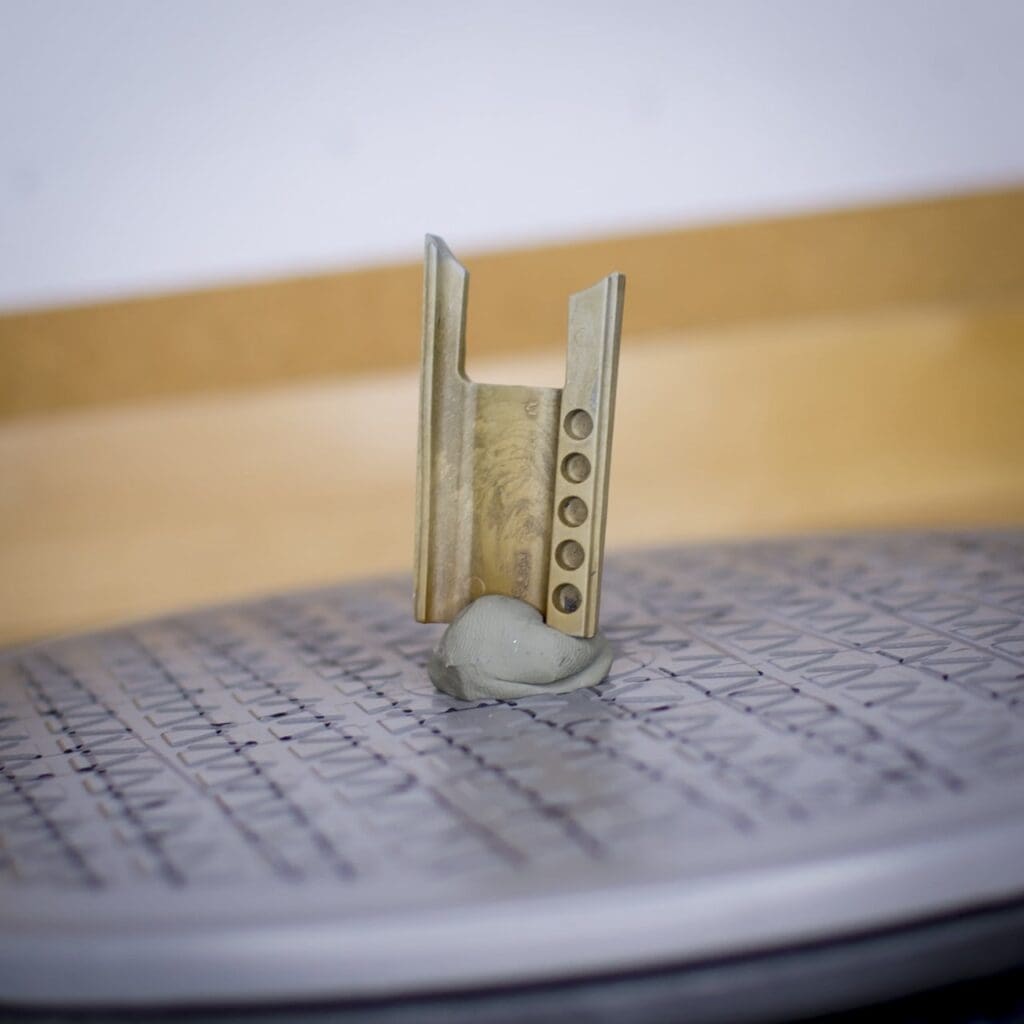

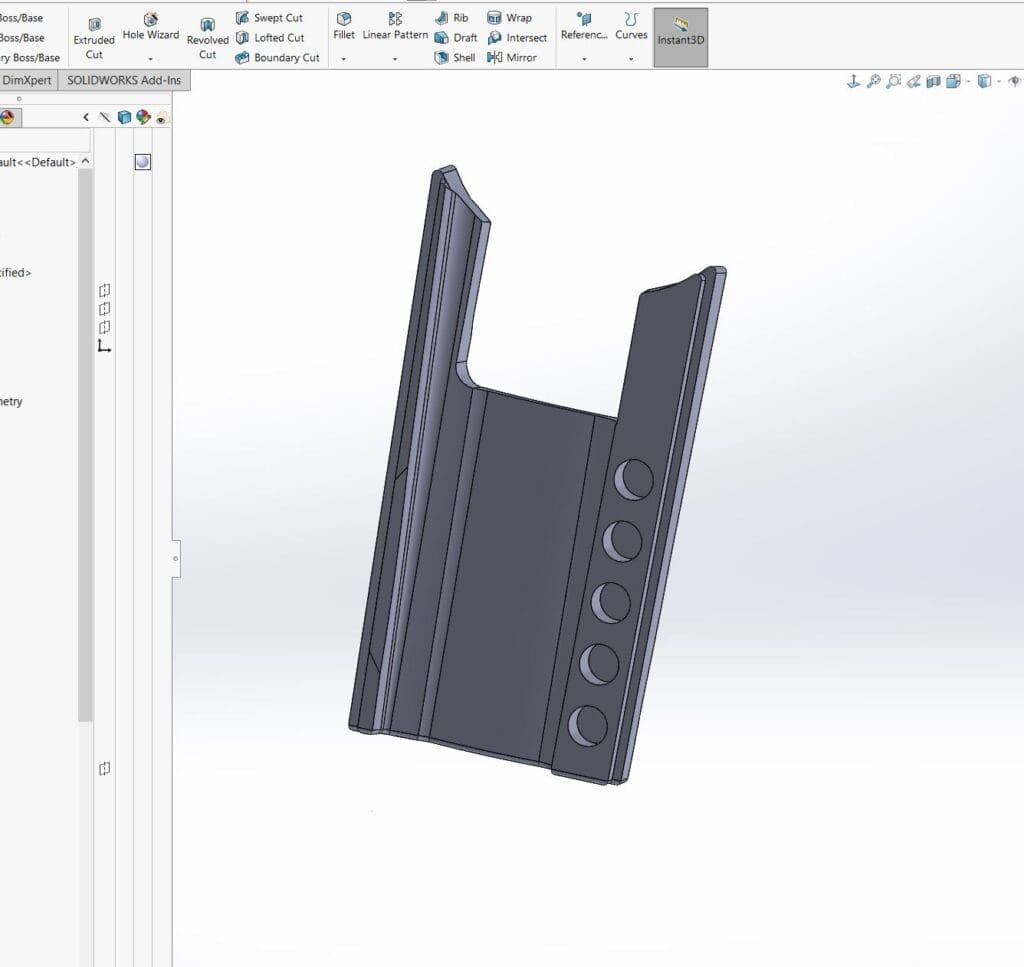

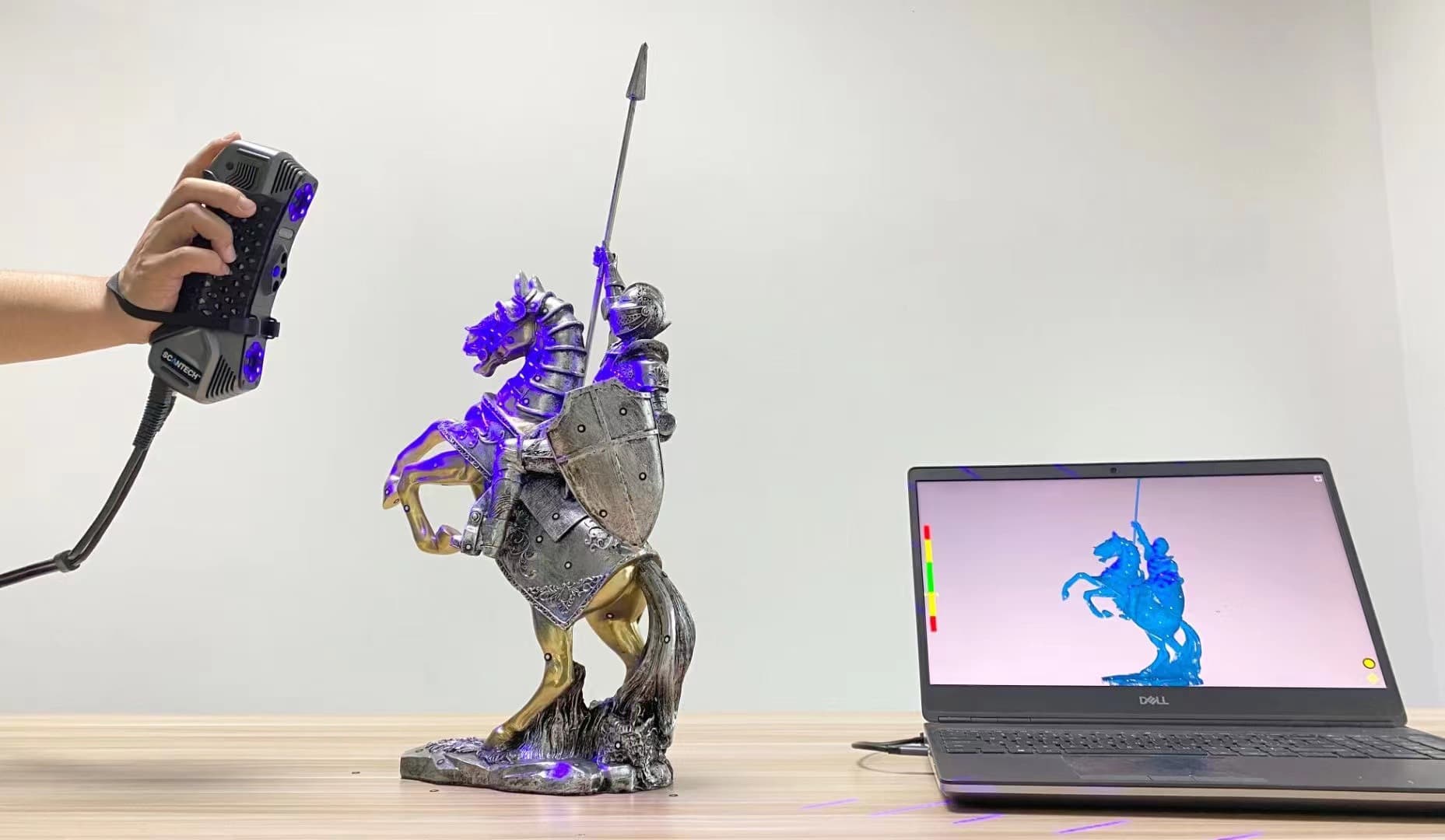

At Digitize Designs, we make the transition from physical objects to precise CAD data smooth and straightforward. Our process starts with detailed 3D scanning, followed by careful data refinement and accurate CAD modeling. We ensure each digital model precisely matches the original object. Whether you’re in aerospace, medicine, or any other field, we deliver in formats like STEP, IGES, and SolidWorks, customized to meet your specific needs. Trust us for precise, dedicated service that turns your physical components into high-quality digital assets.

Diverse Applications of Reverse Engineering:

- Product Refinement: Enhancing legacy items or amplifying current designs.

- Legacy Component Revival: Reimagining designs when foundational CAD data is misplaced.

- Tailored Solutions: Modifying standard components for exclusive applications.

- Innovative Prototyping: Designing fresh prototypes inspired by existing models.

- Component Insight: Dissecting competitor goods to decode design and functionality.

- Reproduction: Replicating components without trespassing intellectual boundaries.

- Digital Conservation: Digitally preserving distinctive parts for future extrapolation.

- Quality Assurance: Benchmarking the final product against its foundational CAD design.

- Virtual Immersion (VR): Sculpting digital renditions for immersive VR explorations.

- Animation: Crafting meticulous 3D replicas primed for animation and special effects.