Why Choose FARO Quantum Max FaroArm®?

When precision is paramount and measurement versatility is essential, Quantum Max FaroArm® are the ultimate choice for quality control and inspection tasks. Their unmatched accuracy, reaching down to 9 microns, guarantees precise and repeatable measurements, ensuring the highest quality standards for your components. The extended measurement range, ranging from 2.5 to 4.5 meters, allows these arms to tackle a wide range of part sizes, eliminating the need for multiple measuring devices and simplifying your measurement process.

1

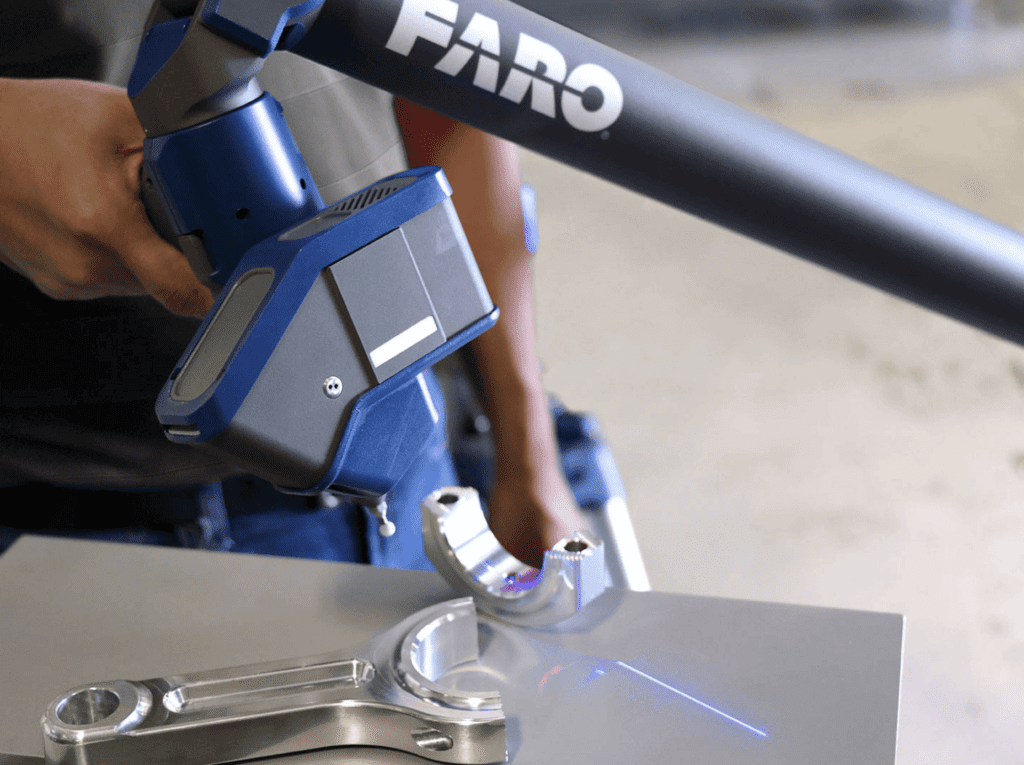

Unmatched Precision

Quantum Max FaroArm® stand as a testament to precision, redefining accuracy standards with an astonishing capability to achieve measurements as low as 9 microns (0.0009 mm). These portable Coordinate Measuring Machines (CMMs) instill confidence in measurement results, delivering reliability and repeatability, even when dealing with the most intricate and demanding components.

2

Extended Measurement Range

Quantum Max FaroArm® offers an exceptional measurement range spanning from 2.5 to 4.5 meters. This broad range grants these portable CMMs the versatility to effortlessly handle components of varying sizes, from small and intricate parts to sizable assemblies. By eliminating the need for multiple measuring devices, Quantum Max FaroArm® streamline the measurement process, enhancing efficiency and productivity.

3

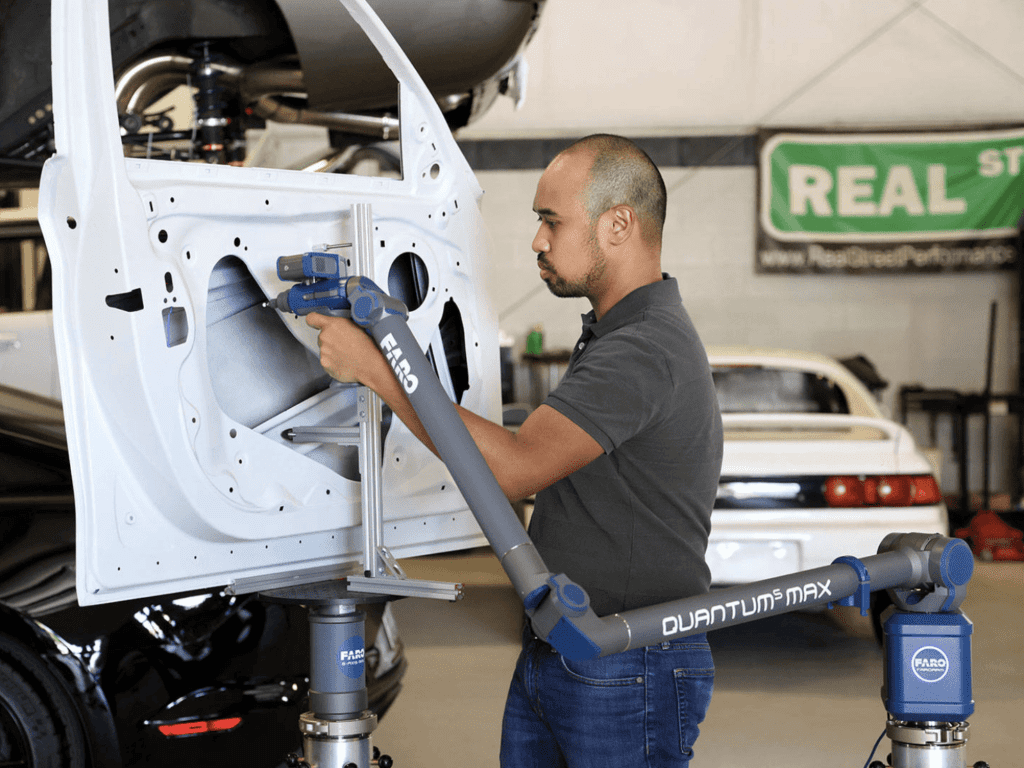

Lightweight and Ergonomic Design

Crafted with user comfort in mind, Quantum Max FaroArm® features a lightweight and ergonomic design. This thoughtful approach ensures that operators can maneuver the arms with ease, reducing operator fatigue during prolonged measurement sessions. The ergonomic grip and well-balanced structure further enhance usability, making Quantum Max FaroArm® an ergonomic and practical choice for precision measurement tasks.